Forging is a metalworking process that has existed for thousands of years and remains an important manufacturing technique today. There are several forging methods available, each with advantages and disadvantages. One of the most popular methods is impression die forging, which involves pressing a metal piece between two dies to shape it accordingly.

Impression die forging can be an excellent solution for numerous applications. However, it is crucial to understand when it is the best option. This article will dive into this particular technique and explore the best applications for this forging method.

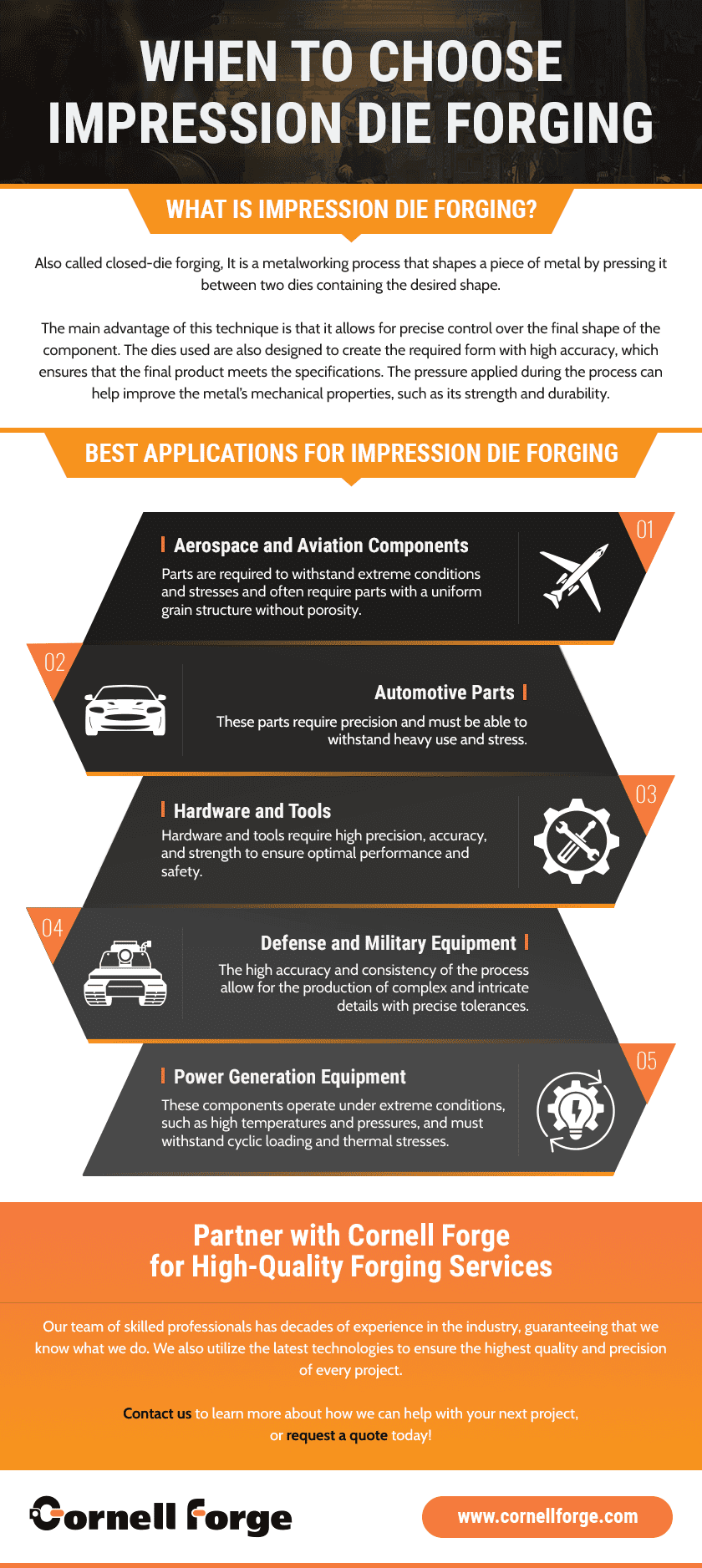

What Is Impression Die Forging?

Also called closed die forging, impression die forging is a metalworking process that shapes a piece of metal by pressing it between two dies containing the desired shape. The process begins with a metal piece — a billet or workpiece — that is heated until it reaches a plastic state. Then, the heated workpiece is placed between the two dies, and pressure is applied to deform the metal into the required structure.

One of the primary advantages of this forging technique is that it allows for precise control over the final shape of the component. The dies used are also designed to create the required form with high accuracy, which ensures that the final product meets the specifications. Additionally, the pressure applied during the process can help improve the metal’s mechanical properties, such as its strength and durability.

Best Applications for Impression Die Forging

Impression die forging is a versatile process that can produce a wide range of high-quality metal components. Some of the best applications for this technique include the following:

Off-Highway Components

The Off-Highway industry has a large variety of different equipment and components, which all require strength, durability, as well as near-net precision. These high performing components are safety critical items where an impression die forging is required to ensure there is no failure of performance.

Impression die forging can produce parts with high accuracy and consistency, which is essential in the engine and landing gear parts. The process also creates parts with a uniform grain structure and without porosity. This results in parts with improved mechanical properties and resistance to fatigue and failure.

Oil & Gas Components

Many components utilized in the Oil & Gas industry, including hammer unions, valve bodies, and other fittings, are manufactured using impression die forging. This technique creates superior strength and durability for the extreme conditions of Oil & Gas drilling and pumping.

Agriculture Components

Impression die forgings are heavily utilized in the agricultural industry due to the importance of having durable and reliable equipment that can perform for millions of cycles. Tractors and combines require forgings to withstand the impact involved in farming and earth moving.

Defense and Military Equipment

Defense and military applications using this forging technique include weapon components and vehicle parts. The high accuracy and consistency of the process allow for the production of complex and intricate details with precise tolerances. This makes it the best method for manufacturing gun barrels, ammunition, and missile components. Additionally, impression die forging can produce vehicle parts like suspension, steering, and drivetrain components.

Transmission Components

Impression die forging is widely used in transmission components due to forging’s superior strength to weight ratio which is an advantage in many industries including gear boxes, automotive , trucks, ATV’s, UTV’s, etc. These components operate under extreme conditions, such as high temperatures and torques, and must withstand cyclic loading and thermal stresses.

The above industries are only a few of the many that benefit from impression die forgings, such as power generation, aerospace, hardware and tools, motorcycle, and many others.

Partner With Cornell Forge for High-Quality Forging Services

Looking for a trusted partner for your next metal forging project? Cornell Forge is the answer! Our team of skilled professionals has decades of experience in the industry, guaranteeing that we know what we do. We also utilize the latest technologies to ensure the highest quality and precision of every project.

Contact us to learn more about how we can help with your next project, or request a quote today!