Trucking is vital to a healthy economy, as this industry keeps the American supply chain going. From commercial goods to technology to medical supplies, trucks transport these important goods where they need to go to supply American consumers. As such, it is critical to increase the work-life of trucks by developing truck components that are strong enough to keep the country on the move.

At Cornell Forge, we offer commercial forged products and truck steering components to our customers’ specifications. With nearly a century of experience, we craft high-quality truck components to guarantee superior performance.

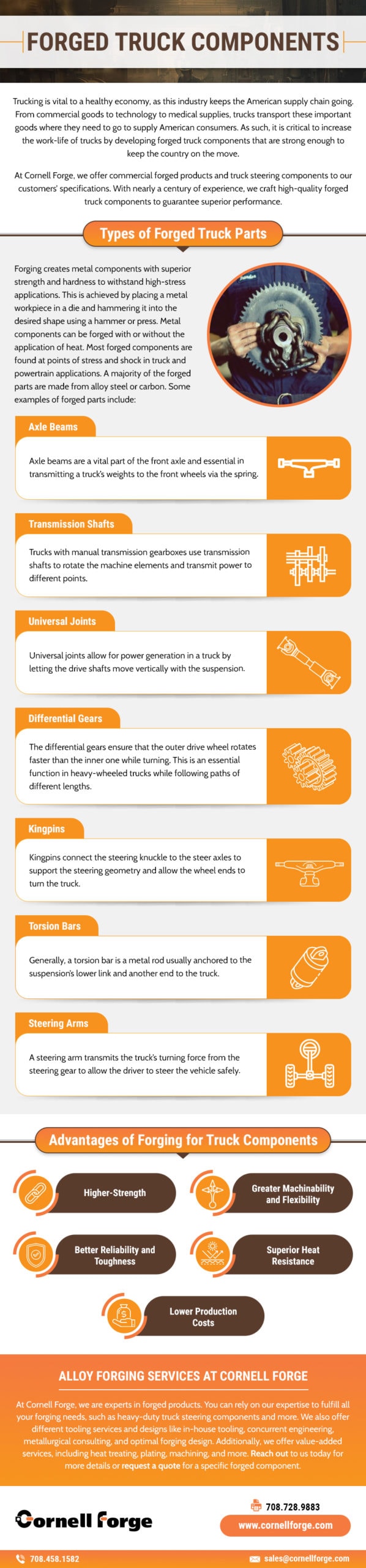

Types of Truck Parts

Forging creates metal components with superior strength and hardness to withstand high-stress applications. This is achieved by placing a metal workpiece in a die and hammering it into the desired shape using a hammer or press. Metal components can be forged with or without the application of heat. Most forged components are found at points of stress and shock in truck and powertrain applications. A majority of the forged parts are made from alloy steel or carbon. Some examples of forged parts include:

- Axle beams: Axle beams are a vital part of the front axle and essential in transmitting a truck’s weights to the front wheels via the spring.

- Transmission shafts: Trucks with manual transmission gearboxes use transmission shafts to rotate the machine elements and transmit power to different points.

- Universal joints: Universal joints allow for power generation in a truck by letting the drive shafts move vertically with the suspension.

- Differential gears: The differential gears ensure that the outer drive wheel rotates faster than the inner one while turning. This is an essential function in heavy-wheeled trucks while following paths of different lengths.

- Kingpins: Kingpins connect the steering knuckle to the steer axles to support the steering geometry and allow the wheel ends to turn the truck.

- Torsion bars: Generally, a torsion bar is a metal rod usually anchored to the suspension’s lower link and another end to the truck.

- Steering arms: A steering arm transmits the truck’s turning force from the steering gear to allow the driver to steer the vehicle safely.

Advantages of Forging for Truck Components

Compared to casting and other metal forming techniques, forging offers many advantages, including:

Higher-strength

Whereas cast components have a random grain structure, forged metals have uniformly sized grains that align with the overall shape of the component, which enhances the forged part’s strength. This way, these parts can easily withstand higher torques.

Greater Machinability and Flexibility

Forging helps to improve chemical uniformity in metals by eliminating impurities and segregations between alloys. By removing impurities, the metal component maintains its structural integrity and increases its machinability.

Better Reliability and Toughness

With the improved metal characteristics, you get a more reliable and tougher material that will last longer.

Superior Heat Resistance

Forged metals have greater structural integrity, which improves their ability to retain their properties in wider temperature ranges.

Lower Production Costs

Forging processes produces metal parts that are almost identical to the desired shape. Through this process, manufacturers produce less scrap because these parts need little to no post-processing.

Alloy Forging Services at Cornell Forge

At Cornell Forge, we are experts in forged products. You can rely on our expertise to fulfill all your forging needs, such as heavy-duty truck steering components and more. We also offer different tooling services and designs like in-house tooling, concurrent engineering, metallurgical consulting, and optimal forging design. Additionally, we offer value-added services, including heat treating, plating, machining, and more. Reach out to us today for more details or request a quote for a specific forged component.