Equipment used in the agricultural industry faces some of the most significant challenges to its durability. Downtime due to equipment damages and repairs is costly, increasing the demand for more durable parts and components. Forged parts can be crafted specifically to meet these challenges, ultimately extending the life cycle of agricultural equipment and reducing operating costs.

Cornell Forge has 90 years of experience in the forging industry. We have the necessary knowledge and experience required to meet the specific demands presented by agricultural applications. We provide custom forged parts with the strength and durability required to keep agricultural equipment performing at its highest level.

Types of Forged Parts for Agriculture

Forged parts prolong the life cycle of agricultural equipment, offering the most reliable means of maintaining equipment. Though steel-cast parts can come at a lower initial cost, they lack the strength and resistance to wear provided by forged parts. Some common forged components used in the agricultural industry include:

- Sprockets

- Spacer plates

- Yokes

- Chain links

- Gearbox components

- Combine fingers

- Shafts

- Spindles

- Flanges

- Tie rods

- Wear bars

- Grain augers

- Universal joints

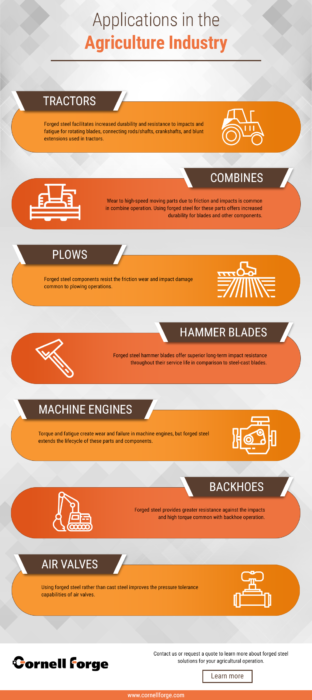

A wide range of agricultural applications use these and other forged parts. The preference for forged parts throughout the agricultural industry relates to the advantages they provide in various applications such as:

- Tractors. Forged steel facilitates increased durability and resistance to impacts and fatigue for rotating blades, connecting rods/shafts, crankshafts, and blunt extensions used in tractors.

- Combines. Wear to high-speed moving parts due to friction and impacts is common in combine operation. Using forged steel for these parts offers increased durability for blades and other components.

- Plows. Forged steel components resist the friction wear and impact damage common to plowing operations.

- Hammer blades. Forged steel hammer blades offer superior long-term impact resistance throughout their service life in comparison to steel-cast blades.

- Machine engines. Torque and fatigue create wear and failure in machine engines, but forged steel extends the lifecycle of these parts and components.

- Backhoes. Forged steel provides greater resistance against the impacts and high torque common with backhoe operation.

- Air valves. Using forged steel rather than cast steel improves the pressure tolerance capabilities of air valves.

Cornell Forge’s closed die steel forging process produces improved strength-to-weight ratio, structural integrity, and long-term operating cost advantages.

Leaders in Manufacturing Agricultural Forgings

Cornell Forge produces a wide array of complex parts from our world-class, centrally located supply base in Chicago. The many advantages we offer our agricultural clients through our forging and value-added services include:

- Custom part designs and quality assurance

- Flexible capacity and inventory solutions

- Short lead-times and dependable delivery

- Globally competitive pricing

- Responsive customer service

Our team boasts an exceptional record of providing net, near net, and finished commercial forged products to the unique needs and specifications required by our customers. We demonstrate our dedication to the highest levels of quality through operational commitments like:

- ISO 9001:2015 Certification

- PED (Pressure Equipment Directive) Certification

- Maintaining a Non-Union Shop

Cornell Forge has accumulated a high level of expertise in supplying forged steel agricultural parts over the past 90 years. Using agriculture machine forged parts increases equipment uptime and has a beneficial long-term impact on the bottom line.

Contact us or request a quote to learn more about forged steel solutions for your agricultural operation.