Precision Metal Forging for Critical Industrial Applications

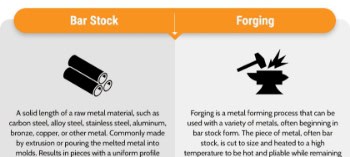

The United States has long been a global leader in advanced metal manufacturing, and forging in the USA continues to play a vital role in industries that demand strength, reliability, and performance. From aerospace and defense to heavy equipment and energy, forged components remain essential where failure is not...