Forging is a process by which the metallurgical and mechanical properties of a metal are optimized by using compressive forces like pressing, hammering, or rolling. Forging metals is a time-saving and cost-efficient method of creating products with high ductility and improved resistance to impact and load fatigue. Forging can be used with a variety of metals, including stainless steel, carbon steel, and other metal alloys.

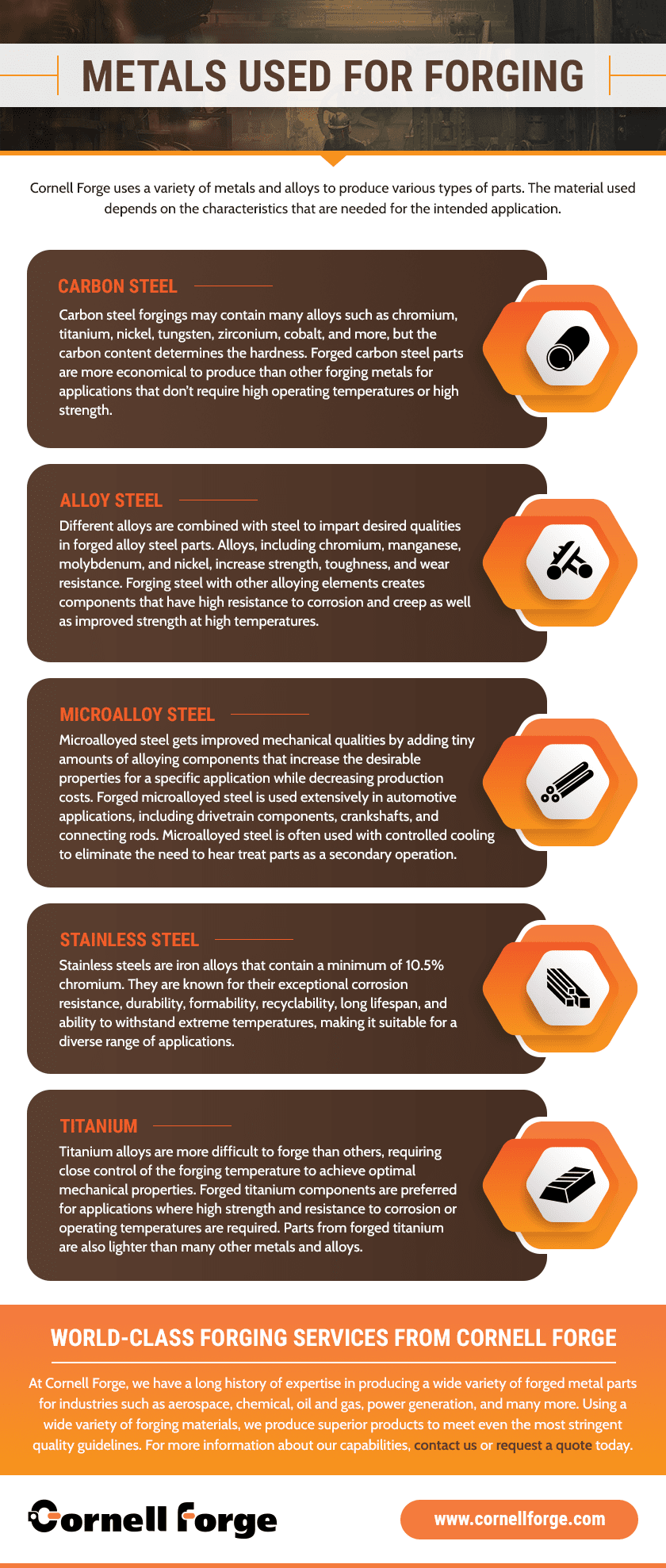

Metals Used For Forging

Cornell Forge uses a variety of metals and alloys to produce various types of parts. The material used depends on the characteristics that are needed for the intended application.

Carbon Steel

Carbon steel forgings may contain many alloys such as chromium, titanium, nickel, tungsten, zirconium, cobalt, and more, but the carbon content determines the hardness. Forged carbon steel parts are more economical to produce than other forging metals for applications that don’t require high operating temperatures or high strength.

Alloy Steel

Different alloys are combined with steel to impart desired qualities in forged alloy steel parts. Alloys, including chromium, manganese, molybdenum, and nickel, increase strength, toughness, and wear resistance. Forging steel with other alloying elements creates components that have high resistance to corrosion and creep as well as improved strength at high temperatures.

Microalloy Steel

Microalloyed steel gets improved mechanical qualities by adding tiny amounts of alloying components that increase the desirable properties for a specific application while decreasing production costs. Forged microalloyed steel is used extensively in automotive applications, including drivetrain components, crankshafts, and connecting rods. Microalloyed steel is often used with controlled cooling to eliminate the need to hear treat parts as a secondary operation.

Stainless Steel

Stainless steels are iron alloys that contain a minimum of 10.5% chromium. They are known for their exceptional corrosion resistance, durability, formability, recyclability, long lifespan, and ability to withstand extreme temperatures, making it suitable for a diverse range of applications.

Depending upon the choice of material, forged metal parts are appropriate for various applications in multiple sectors. Each of these forging metals provides many benefits when used to create mechanical parts.

Benefits of Forging Carbon, Alloys, & Micro Alloys

There are many advantages of using carbon, alloys, and micro alloys for forging, including:

- Benefits of Carbon Steel. Forging carbon steel produces parts that are resistant to abrasion, fatigue, and wear.

- Benefits of Forging Alloys. Forging alloys offers benefits such as availability, lower costs, superior mechanical properties, and increased ease of processing.

- Benefits of Forging Micro Alloys. Depending upon the alloy as well as forging and cooling temperatures, micro alloys offer advantages such as improved high cycle fatigue resistance and increased strength demonstrated in higher static and dynamic loads.

Forging creates parts that are cost-effective, strong, reliable, and formable in a variety of shapes. The machine forging process, combined with forging materials such as carbon steel, alloys, and microalloyed steel, can impart superior metallurgical properties applicable to a wide range of uses. Cornell Forge is proud to work with all of these materials to suit customer specifications and requirements.

World-Class Forging Services from Cornell Forge

At Cornell Forge, we have a long history of expertise in producing a wide variety of forged metal parts for industries such as aerospace, chemical, oil and gas, power generation, and many more. Using a wide variety of forging materials, we produce superior products to meet even the most stringent quality guidelines. For more information about our capabilities, contact us or request a quote today.